Cannabis

Cocoa

Coffee

Dehusking

Depulping

Drying

Drying Fruit & Veg.

Essential oils

Extraction

Food Innovation

Fruit & Vegetables Snacking

Insects

Non Volatiles extraction

Peppercorn

Sterilization

Vanilla

Essential oils

Disrupt the essential oil market with a unique, innovative and sustainable extraction technology.

- Extract essential oils in only a few seconds

- Improve extraction yields

- Preserve thermosensitive compounds

- No degradation of the biomass for further extraction

D.I.C. is applied as an alternative or in combination with standard distillation processes (Hydrodistillation, steam distillation, microwave distillation, ultrasound assisted …).

Reduce energy consumption by a factor 3 to 10.

D.I.C. extracted essential oils have spent only a few seconds at high temperature. We manage to preserve the more sensitive compounds for perfume innovative scent and reach a higher antioxidant activity for aromatherapy applications.

D.I.C. is quite effective on leaves (peppermint, cannabis, eucalyptus, patchouli, laurel, rosemary), flowers (lavender, ylang-ylang), roots (ginger, turmeric, vetiver) and wood (sandalwood, rosewood, cedar).

Essential oil extraction process with D.I.C.

RAW MATERIAL

fresh or dry

→

D.I.C.

2-3 min

→

EMULSION

COLLECTION

→

EMULSION SEPARATION

by hydro-distillation

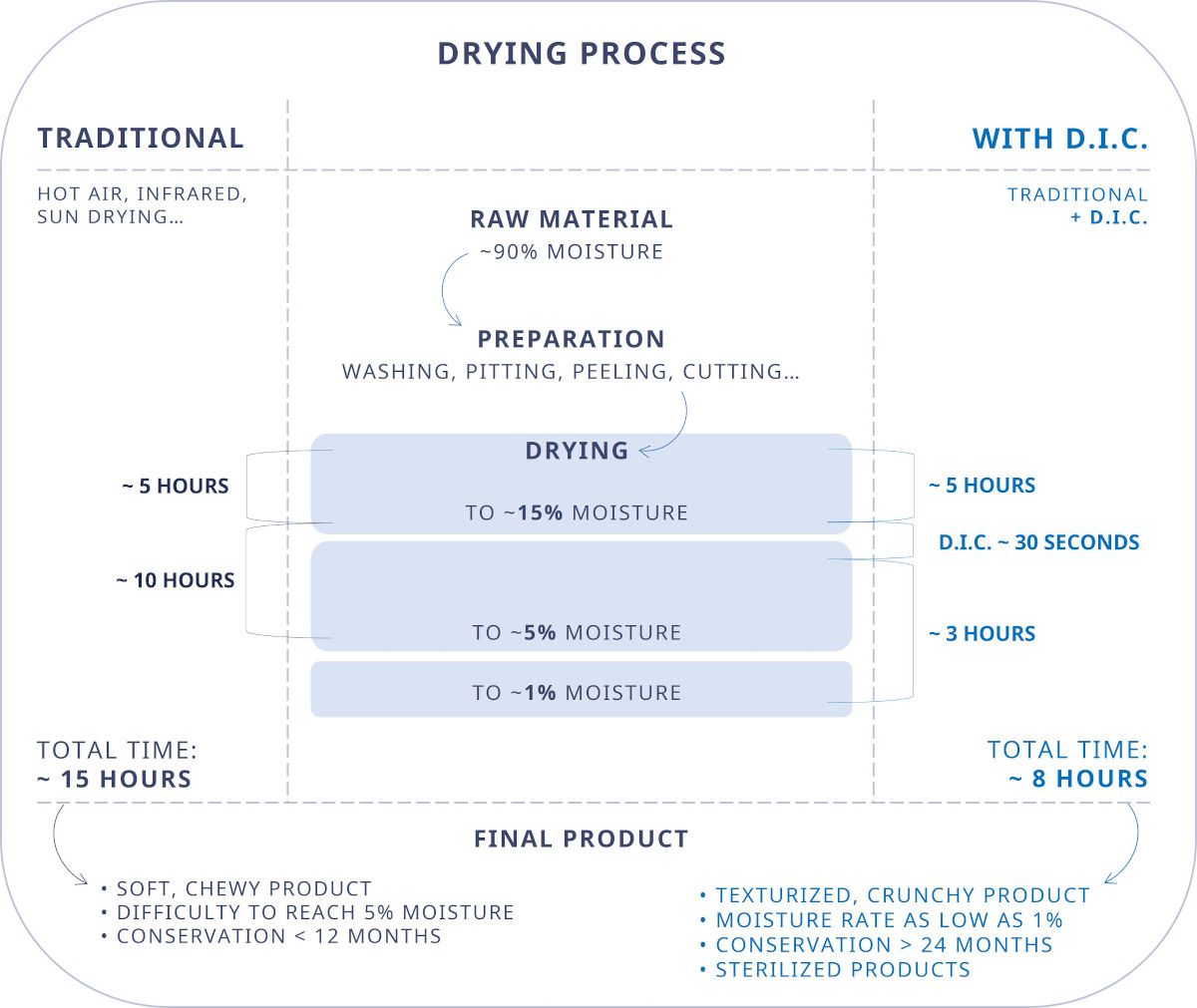

Drying fruits and vegetables

Drying

D.I.C.’s thermo-mechanical action is often exploited to enhance food drying performances, to develop innovative products or optimize production lines, and to reduce processing costs.

By opening the pores of the products, all the way to their core, water that is usually trapped in the heart of the matrice can be simply and completely drawn out of it, to reach a global moisture rate as low as 0%.

Depending on what you seek, you can play on all three D.I.C. parameters to get a more or less texturized and dried effect: fruit & veggie crisps, ingredient powders, diced incluson food for soups and more…

ALL THE INGREDIENTS…

Fruits and vegetables

Pulses and other plant proteins

Meats and cheeses…

HIGH QUALITY RESULTS

Moisture rate as low as 0%

Faster drying

Improved grinding (no stickiness issues)

Quick and tasty rehydration

Flavours preservation

…AND ALL THE TEXTURES

Crunchy, crispy

Soft and bouncy

Sliced, diced, grinded and powdered…

SIMULTANEOUS KILL STEP

D.I.C. is a kill step in itself.

Every cycle ensure the highest levels of food safety and is an easy way to reduce food waste due to food deterioration.

Fruit & Vegetable Snacking

Whether you wish to open new prospects on the snack food market, or simply boost an actual range of healthy snacks, D.I.C. offers a plethora of development opportunities for the snacking segment.

Dry Fruit and Vegetable process with D.I.C.

RAW FRESH MATERIAL

Apple, Carrot, Beetroot…

~85-95% water content

→

PEELING AND CUTTING

Shape it as you want:

slices, fries, cubes…

→

STANDARD AIR DRYING

Down to a 15 to 25%

moisture content

→

D.I.C.

Puffing the structure

A few seconds

→

FINAL DRYING

Hot air or infrared drying

Quickly goes down to 3%

SURPASS THE STANDARDS

Texturize products that extrusion cannot texturize

Extend shelf-life duration to the very long term

5 log sterilization

MEET CONSUMERS NEEDS

High nutritional benefits

No oil, no frying

Zero additive

Top organoleptic qualities

DISRUPT THE SNACKING CODES

Make healthy snacks fun and attractive to kids

Develop new, innovative, healthy snacks

SUSTAINABILITY MADE TASTY

D.I.C. also rimes with valorization: transform downgraded fruits and vegetables into crunchy, tasty crisps with a near infinite shelf-life duration.

HEALTH BENEFITS

D.I.C.’s thermomechanical action makes it possible to treat the products 100% naturally, without adding any oil, sugar, nor additive/preservative.

Nutrients and fibers are kept intact to the consumer’s health benefit.

Dry Vegetable Healthy Snacking

Sweet Potato

Bell Pepper

Broccoli

Carrot

Onion

Beets

Dry Fruit Healthy Snacking

Apple

Tomato

Peach

Strawberry

Fig

Mango

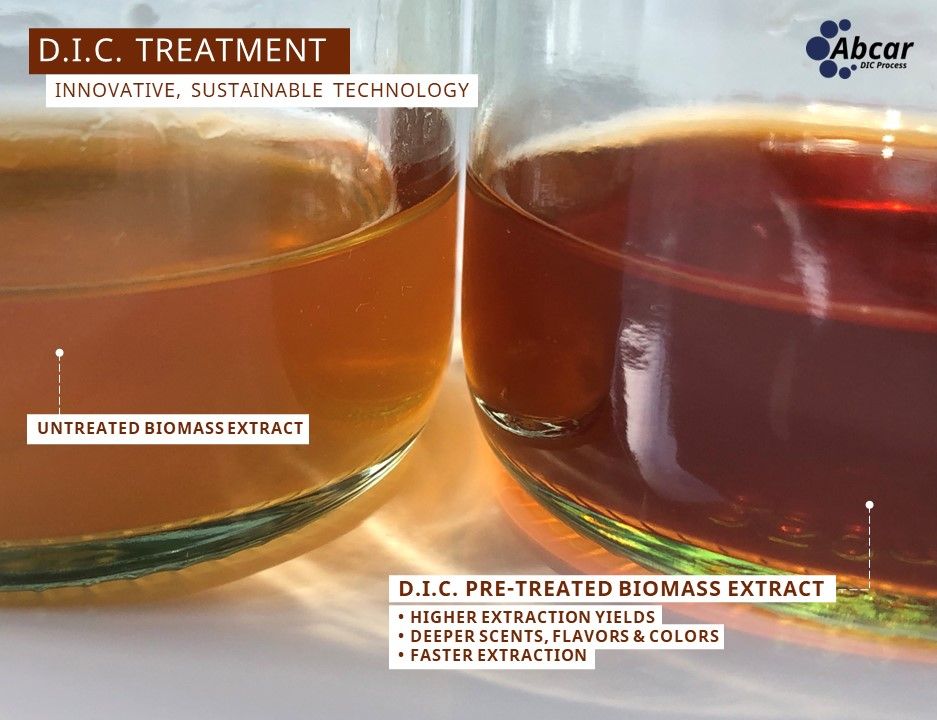

Extraction

Among its wide range of applications, the D.I.C. features are of great interest for the green extraction sector.

Its effects represent a major asset for the direct extraction of volatile compounds (essential oils), and for non-volatile compounds extraction (lipids, antioxidants…) as a pretreatment of the matrices.

Nonvolatile compounds

For compounds like oils, antioxidants… D.I.C. comes in combination with existing technologies (CO², solvents, press...) to improve the extraction.

By expanding the biomass structure, it:

- Increases extraction yields

- Takes less time and energy to complete the extraction

- Improves the extracts quality

Volatile compounds

For essential oils, D.I.C. comes as an alternative to the classic distillation methods, with benefits including:

- Preservation of thermosensitive compounds

- Non-degradation of the matrix which can then be better valorized

- Significant reduction of energy needs

SUSTAINABLE

PROCESS

WATER

SAVING

LOW

CONSUMPTION

COSTS

REDUCTION

Food Innovation

D.I.C. was first designed to boost innovation in the Food Industry. It is a sustainable answer to the increasingly important challenges that face the agrifood industry.

D.I.C. disrupts the Food Market, optimizing production processes and answering the growing demand for food products that are healthier and better for the environment.

It nurtures progress in 3 key pillars for a better, more proficient and virtuous industry:

INNOVATION

New products

New textures

New concepts

SUSTAINABILITY

Product valorization and waste reduction

Loss reduction with sterilization

Natural long shelf-life duration

Low energy consumption

HEALTH

Food safety (5Log kill step)

Nutrients preservation

No added sugar, oil, additive

Antinutrients elimination

As a powerful opportunity booster, D.I.C. enables groups and companies to stand out on the market with original, high-quality, and reliable products.

Whether you want to develop an innovative, healthy, and tasty snack product, a natural alternative to ultra-processed food, or to ensure the highest level of food safety, D.I.C. can be the solution to your problematic, and to reach your marketing goals.

Coffee

Revolutionize the coffee industry, introducing new quality standards on the market, with more sustainable processes throughout the whole chain.

- Deactivate enzymes to stop green coffee oxidation

- Texturize to increase compounds availability

- Improve aromas, up to +13 SCA points

- Reach higher roasting grades without burning

Coffee process with D.I.C.

RAW MATERIAL

Green beans

→

D.I.C.

30 seconds

→

STANDARD PROCESS

Roasting / extraction

Insects

Upgrade your transformation process, boost your production, and optimize your energy performance with D.I.C.:

- Prevent enzymatic oxidation

- Accelerate drying time

- Optimize biomass extraction and purification

- Ensure food safety

Insects process with D.I.C.

RAW LARVAE

alive

→

D.I.C.

1 min

→

DRYING

Faster, sterilized, no oxidation

→

EXTRACTION

No enzymatic oxidation over time

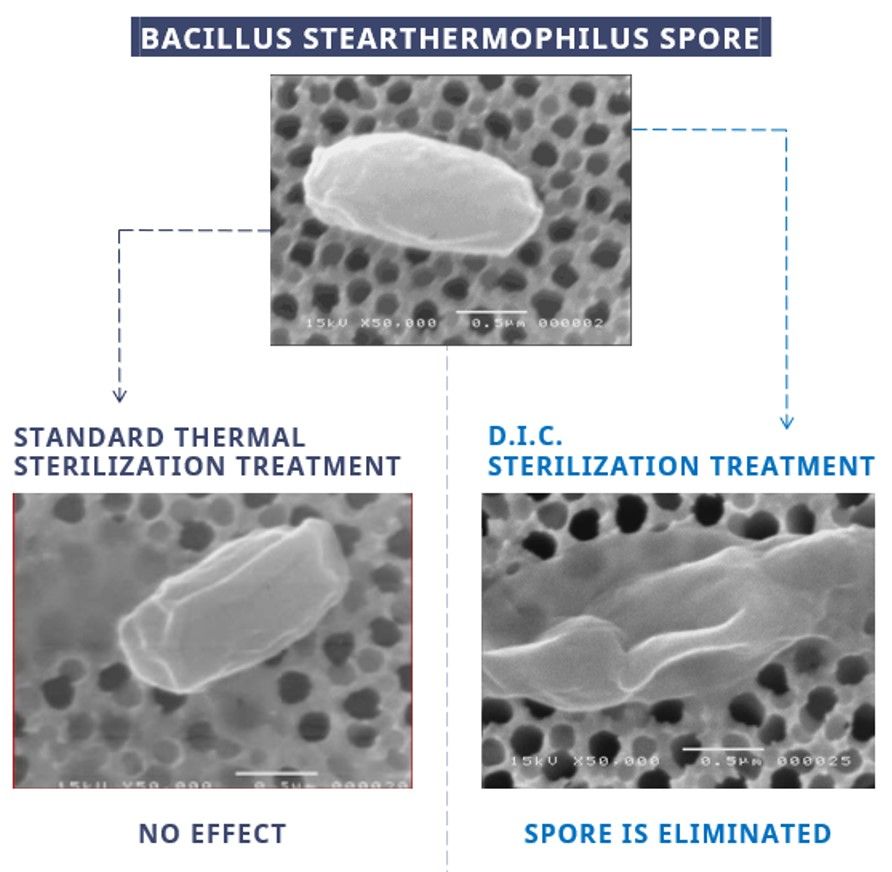

Sterilization

More effective than any standard steam sterilization technologies, D.I.C. can reach a 5 log sterilization in only a few seconds.

The process is precisely adapted to each matrice, ensuring no degradation of the product compounds.

HIGHEST QUALITY STANDARDS

SPORES AND BACTERIA ELIMINATION

(E.Coli, Salmoella, Listeria…)

ENZYMATIC DEACTIVATION

FRESH OR DRY

An efficient and economical alternative to the classic sterilization systems (autoclave, UV sterilizer, gamma irradiation…). Thanks to a fast processing time of a few seconds only per batch, D.I.C. does not alter the products, preserving both their organoleptic and nutritional values.

Compliant matrices:

- Nuts: walnuts, almonds, cashews, pistachio, hazelnuts…

- Pulses, seeds, grains, cereals: wheat, rice, lentils, chickpeas, soy, sunflower seeds, pumpkin seeds, sesame, cocoa…

- Plant-based matrices: vanilla pods, aromatic leaves, peppers, sundried tomatoes, dried garlic, cannabis…

- Animal matrices: insects, dried meat, dried fish…

- Whole spices, dried: peppercorn, cinnamon, ginger, turmeric, juniper berry…

Cannabis

Explore a whole new approach to cannabis processing, with original, innovative treatments that guarantee high quality products, reaching new standards on the market.

- Sterilization for medical use

- Essential oil extraction with no CBD degradation

- Improved accessibility for solvent extraction

- Fast controlled decarboxylation

- Faster drying with color preservation

Non-volatile compounds extraction

Boost extraction yields and develop new extract qualities.

D.I.C. pre-treatment increases compounds availability, making it possible to exploit the matrix potential to its maximum.

- Improve extraction yields

- Introduce new standards

- Optimize the matrix compounds potential

Optimized extraction process with D.I.C.

RAW MATERIAL

fresh or dry

→

D.I.C. PRE-TREATMENT

1 min

→

OPTIMIZED EXTRACTION

(press, solvent, co²…)

Cocoa

Introducing D.I.C. to the cocoa market, for a more efficient production chain:

- Stop fermentation before or after drying

- 5 log kill step, eliminates spores

- Extend conservation duration, prevents molds

- Improved dehusking

- New ways of roasting

Cocoa process with D.I.C.

COCOA BEANS

Dried

→

D.I.C. PRE-TREATMENT

A few seconds

→

STANDARD PROCESS

(Long shelf life / Improved dehusking / Roasting)

→

D.I.C. ROASTING

90 seconds to 3 min

→

A NEW WORLD

Simple process line / New products / New tastes

Untreated bay powder

D.I.C. treated bay powder

Avoid oxidation - Preserve polyphenols

Depulping

Natural treatment to boost and preserve your bay products like cascara, açai, etc.

- Prevent oxidation of the pulp

- Facilitate extraction

- Improve separation of the pulp and the stone

- Accelerate drying time

Depulping process with D.I.C.

BAY PRODUCT

fresh

→

D.I.C.

1 min

→

DEPULPING AND DRYING

Easier pulping, faster drying

→

FINAL POWDER

No oxidation, no mould, no spores.

Vanilla

Refine your vanilla offer, curating the highest quality range of beans and ingredients on the market with optimum aromas and sents.

- Improve extraction and valorisation of the pods

- Accelerate drying time

- Minimize production waste

- Ensure food safety

Vanilla process with D.I.C.

VANILLA PODS

Pre-dried

→

D.I.C.

A few seconds

→

DRYING

Better grinding. No spores, no bacteria, no mold.

→

EXTRACTION

Better accessibility

Peppercorn

Open new market doors with unique peppercorn shapes and colors.

- Sterilization for food safety and waste reduction

- Anti-oxidation for a unique, green dried bay color

- Texturization for a full, rounded dried bay shape

Fresh peppercorn process with D.I.C.

PEPPERCORN

Fresh

→

D.I.C. TREATMENT

30 seconds

→

OPTIMIZED DRYING

No oxidation, faster drying, lower final moisture

→

FINAL PRODUCT

Free from spores, green color

Dry peppercorn final process with D.I.C.

PEPPERCORN

Dry

→

D.I.C. TREATMENT

30 seconds

→

FINAL PRODUCT

Free from spores, molds, bacterias

Dehusking

A flash texturation (1 to 2 seconds) to help shell removal on dried nuts and grains, with no impact on the core product

- Texture the skin only, and preserve both the raw material and its nutritional values

- Make silver skin removal quick and easy, and preserve up to x3 more antioxidant in the coffee beans.

- Brush off cashew and cocoa shells, with no force.

- No product loss during dehusking.

Dehusking process with D.I.C.

NUTS, SEEDS, GRAINS

dried

→

D.I.C. TREATMENT

1 to 2 seconds

→

SHORT DRYING

→

DEHUSKING

brush off skins and shells effortlessly