We design our D.I.C. equipment to fit the current needs and requirements of the industry.

Our machines offer a neat, hygienic design, easy to clean in place and requires low maintenance.

D.I.C. equipment are low-carbon and energy efficient. They represent a sustainable alternative (or implementation) to many existing processes in the Food and Cosmetic sectors: extraction, drying, sterilization…

Innovation at Lab & Production Scales

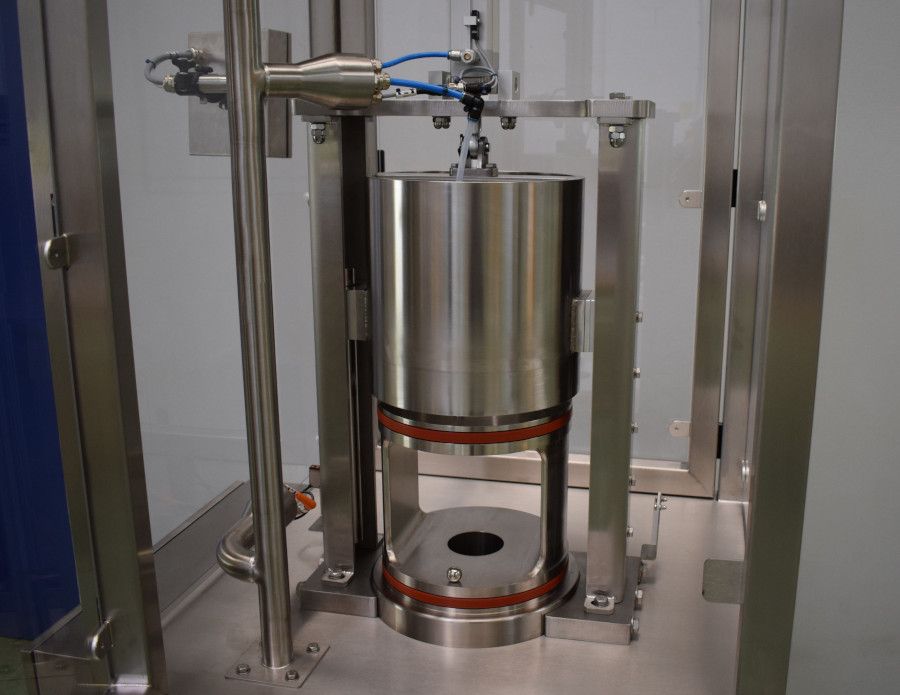

Our range comprises an industrial (production) model and a lab scale (pilot) model to answer all needs and interests.

LAB

(PILOT)

CAPACITY: 3l per batch

VELOCITY: 40 batches/h

YIELDS: 10-40 kg/h

DATA RECORDING: Trace your R&D

INDUSTRIAL

(PRODUCTION)

CAPACITY: 15l per batch

VELOCITY: 60 batches/h

YIELDS: 100-400 kg/h

DATA RECORDING: HACCP control

R&D

We are here to guide and attend our clients in their R&D projects, putting our expertise and machinery at their service.

Tailor-made R&D guidance

Based on your specific issues and needs, our team delivers a fastidious D.I.C. R&D design / program.

Working on a new product? Looking for a process optimization?

Let's run D.I.C. Trials

Food

Cosmetics

Aromatherapy

Nutraceuticals

Pet Food

Solve your problems

Texturization

Drying

Extraction, essential oils

Extraction, nonvolatile compounds

Sterilization

Specific product needs

→

Experimental trials

→

D.I.C. parameter optimization

→

Industrialization

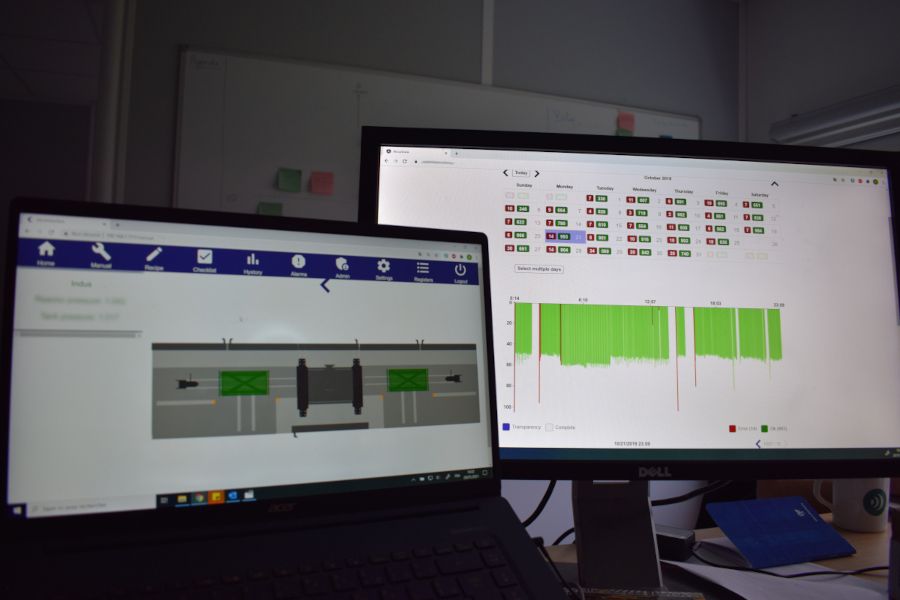

Industry 4.0

To ensure optimum performance and allow continuous improvement, we offer data recording services to monitor the production batch per batch.

Data recording service

A quality monitoring allows you to record production shutdowns and to pinpoint functioning problems. It also enables you to retrieve best practices and to optimize manufacturing activities.

- Quality control

- Real time analysis

- CCP validation

- Secure storage

- Preventive maintenance

QUALITY CONTROL SYSTEM

Real time recording and analysis of sensors validate all cycles. Cycles are uploaded and backed up safely to a dedicated cloud.

Reports can be exported and used as quality certificate.

EFFICIENCY GAIN

Post-analysis of data helps to prevent failure and anticipate maintenance.

In case of failure, remote assistance allows fast identification.

RELY ON DATA

An alarm is triggered in case of invalid D.I.C. cycle, and products can be discarded by the operators.

Controlled data, where every millisecond counts, is the key to maintaining your product quality and standard.

MORE BENEFITS

Get premium assistance from our technical D.I.C. process experts.

Make your production more reliable without hidden costs.

Plug & Play

D.I.C. equipment are sent ready to be plugged with few fittings to make before launching the production.

We assist you in the whole installation process, from recommendation for configurations settings and peripherals choice, to the actual installation step upon reception.